Winter is a challenge for all kinds of cars. Burners do not start. It takes forever to get warm in the car. The consumption is significantly increased. And in winter, the streets smell more intensely than in the rest of the year. In most cars, when the temperature falls below 10 degrees, the exhaust gas purification system is shut down to protect the engine.

Electric cars also have some technical challenges in winter. The current nextmove video is about the winter performance of electric cars in general and about winter suitability, heating, high-voltage battery and fast charging in cold temperatures.

For this purpose we have carried out various tests with the VW ID3 with several vehicles. The results surprised us very much. Concretely, we will get to the bottom of these questions:

- Is the heat pump absolutely necessary?

- How does the battery heating of the ID.3 work in winter?

- Can I preheat the battery via the app?

- Why is the consumption in winter on short trips twice as high as in summer?

- Why does the car charge slower in winter?

- What do I have to do to get full charging power?

- What are the sticking points with e-cars in winter and what are the advantages?

With the electric car, the winter crunch point is not in the engine but in the battery. A cold battery offers less power, less range, it ages faster and can be ni

Not only passengers have comfort needs and want to be chauffeured at a comfortable temperature, but also the battery. At the same time, consumption should not increase too much, or the range should be reduced. This is the task of the so-called thermal management, which most current electric cars have on board. The outside temperatures in all tests were between -2 and +3 °C.

Test no. 1: The cold start of an electric car

You want to start early, the ID.3 stood outside at night, it was frost, the battery is cold, the interior is cold. The car was not preheated and no departure time was programmed. When driving on short distance, the average consumption is 30-40 kWh per 100 kilometers, while in summer less than 15 kWh are needed. Where does that come from?

Of course the interior is completely frozen and it costs a lot of energy to heat it up. But, the ID.3 also warms the battery (thermal management). We have read the values and show what happens.

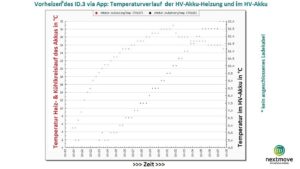

The graphic shows the cold start behaviour of the ID.3 in the high voltage battery range. Besides the interior heating there is a second heating circuit – a floor heating for the battery, so to speak. We can see the values of this battery heating rising relatively quickly to almost 30 °C after the start. But the battery weighs about 400 kg, you have to heat it first and that takes time.

As a result, the battery temperature increases only slowly and with a time delay. After approx. 10 minutes, the underfloor heating switches off, but the residual heat continues to heat the battery. The target temperature for the battery is 13 °C and was reached in the test after approx. 17 min.

Why does the ID.3 do this? On the one hand, to protect the cell chemistry in the battery – i.e. to prevent premature aging of the battery. On the other hand, to enable optimal performance – both during removal (acceleration) and energy recovery (recuperation). And this is exactly what the ID.3 always does when you drive off with a cold battery. That’s why consumption is so high during the first few kilometers. We achieved the magic 13 degrees relatively consistently in all tests – so this seems to be the target value.

Test no. 2: Preheating via App

But there is a smart app for preheating for almost all electric cars or in the car a pre-programming for the departure time. So why not heat the battery before departure? No sooner said than done. We also provide a graphic for this.

When the heater was started, the battery had 4.5 °C and the same thing happens as when starting. By the way, the switch-on threshold is about 8 °C, i.e. if the battery still has residual heat at the start and is above this value, it will not be heated up again.

But what does it cost to „heat up“ the battery once? This was also analyzed.

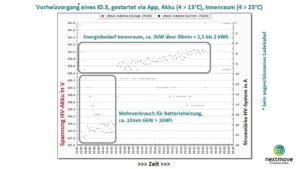

The graph shows voltage and current, multiplied results in the power and thus indirectly the energy consumption for heating in the corresponding time window.

We have previously shown that the ID.3 switches off its battery floor heating after about 10 minutes. And when it comes to energy consumption, we see the same thing in the first 10 min, i.e. a significantly increased consumption. The consumption when stationary is about 9 kW power in the first 10 min. For comparison: 9 kW – that is enough to let an electric car roll along at a constant speed of 50 km/h, and here we use this power for waste heat!

You could also say: We invest it. Because a warm battery is also correspondingly more economical, charges faster and lasts longer. After 10 minutes the values jump and the car then heats only the interior with approx. 3 kW power. Roughly speaking, this combined comfort costs one euro, of which ⅔ for the passengers and ⅓ for the battery.

Critically spoken, one could also say that 30 cent land in the warranty cash of the manufacturer, because the heated Akku comes naturally better over the years and becomes hopefully no warranty case. The unheated battery would age somewhat faster and lose more capacity over the years.

The whole thing always depends on the outside temperature, how long the car was parked before and of course the heating power was lowered later while driving. Whether you preheat the car with the app or drive it cold doesn’t really make a big difference in the overall consumption, because the car behaves the same in both cases. Preheating is of course more comfortable.

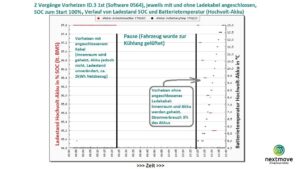

But preheating always costs us a few percentage points of charge and thus also range. Therefore it is much more clever, if possible, to take the river directly still before the start from the Wallbox. This was also tested and the ID.3 surprised us, because it can’t do it. This is also shown by the data.

When preheating on the charging cable the charge level does not change, the interior is heated with the current from the wallbox, but the battery remains at 4.5 °C. That was very surprising. The test was repeated: doors opened, the car ventilated for an hour, charging cable disconnected. Then doors closed, car closed and the heating started again via app.

And lo and behold: unlike before, it heats the battery – with the current from its own battery, as seen on the right in the diagram, the charge level goes down and battery temperature rises.

We confronted VW with it – what does the manufacturer say? Quote: „The topic is well known – a solution is coming in the context of the upcoming software update“. So the all-clear at this point, whereby VW does not write which update is meant. If and when the battery is heated is of course different from manufacturer to manufacturer, a second example follows later.

Winter advantages of electric cars

Of course, electric cars also have advantages in winter, which in our opinion more than compensate for the disadvantages: An auxiliary heater is standard in almost all models, so it costs nothing extra. Preheating is possible via the app or time programming.

If not preheated, electric cars are still warm inside faster than combustion engines. The heater may be left running while sitting in the car while parking, but the engine of a combustion engine may not. That costs 80 € penalty e.g. for ice scraping, which is not necessary in an e-car anyway thanks to air conditioning via app.

The lower operating temperature threshold for the e-car is below the diesel. With normal diesel fuel, the threshold is usually -22 °C. With ID.3, VW says „don’t park below -30 °C for more than 24 hours“, i.e. driving is still possible at -40 °C.

To remind you once again: A car with a combustion engine is not an „automobile“ at all in terms of energy, but actually a moving heater. Approx. 2/3 of the energy is used for heat generation and only a small part for locomotion, so driving is a side effect.

Winter suitability & Heat pump

There is hardly any other topic around the electric car that has more myths and opinions. The ID.3 has them, but not in series. The user is spoilt for choice, because the assembly is not cheap. The feature is VW’s special recommendation in the configurator for about 1250 Euro. VW promises up to 30 percent more range in winter! … not 30 percent less heating, but 30 percent more range, thanks to 30 percent less total consumption.

How is this supposed to work? VW writes about it:

„A highly efficient heat pump system compresses refrigerant under high pressure. The resulting heat is used to heat cold air flowing through it. As a result, less energy from the battery is used for high-voltage heating and there is a range advantage over electric vehicles without a heat pump.“

In the range around 0 °C, VW documents suggest an advantage of 20 percent more range.

When we had seen the VW announcements about the heat pump, we knew that this was a very ambitious announcement that was worth checking out in practice.

Consumption test heat pump

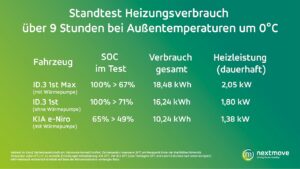

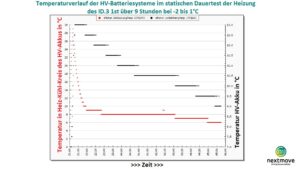

In order to test the efficiency, first two ID.3 with and without heat pump as well as a KIA eNiro with heat pump as a reference were statically operated overnight for nine hours, and the interior was permanently heated to 23 degrees. As far as possible, identical settings were chosen in all cars.

Based on the removable capacity of previous tests, the average permanent heat output was calculated.

The ID.3 with heat pump had the highest consumption of the tested vehicles. Actually the car should be more economical, than the comparison vehicle without heat pump. But, there are vehicles and no standing tools. Such a standing test is only half the truth. Because such a E-car has also a little waste heat from the drive and with some manufacturers is well-known that one catches and uses these losses in the heat pump system also.

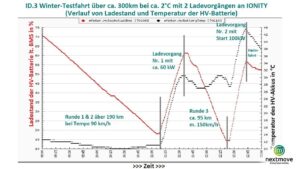

The following day, a test was carried out over almost 300 km in synchronous drive with both ID.3. The graph shows the consumption of the two vehicles according to the on-board computer.

The values of the vehicle without heat pump are on average even slightly below those of the ID.3 with heat pump. The control over the acceptance in the charge state confirmed the value picture. The vehicle without heat pump had after the first two and also after the third round always one per cent more charge state. At the start both cars were always equally fully charged.

We also sent these results to VW and received a reply:

„Without naming further boundary conditions (outside temperatures, preconditioning of the vehicle, settings, …) the described problem is unfortunately not sufficiently analyzable from the point of view of our technicians. Maybe the heat pump was not yet in heat mode but in „dehumidify“ mode (climate)? In principle we hold to our goal of being able to obtain a significant range advantage by the employment of the heat pump technology

This answer is of course a bit evasive. No confirmation of our figures, but also no clear denial. I had of course described the boundary conditions in detail and after a nine-hour endurance test, the battery heating of the first 10 minutes is of no importance. One word in the answer, however, is very exciting, namely the word „objective“. Regular viewers of our videos on nextmove know of course that the ID.3 is not really ready yet. At the end of VW’s answer there was this exciting sentence:

„Regardless of this, we are basically working on a continuous increase in the climate efficiency of our models“

We also sent these results to VW and reply Our assumptions about the test results were also along these lines. With the ID.3, VW has delivered a very good overall package in many respects. But against the background of the numerous problems in the area of software and the loss of time due to Corona, we probably initially concentrated on ensuring that the cars ran more or less trouble-free and put efficiency issues at the back of the list of priorities. With ID.3, there is certainly still a lot of room for improvement in many areas. Of course bugs have to be eliminated first and then the topics can be tackled one after the other. Honestly naturally the advertising statements on the homepage would have to adapt to the heat pump, e.g. in such a way: „Up to 20 per cent more range. The energy saving function will be added in the update by the end of the year“.

Is the heat pump now recommended or not?

As of today we cannot yet give a final answer to the question for ID.3. If VW still increases the efficiency, then we see the target groups approximately in such a way:

- YES: for frequent drivers, long-distance drivers, users from colder regions for whom the purchase price is not so relevant

- NO: for less frequent drivers with limited budget from areas where snow is rather the exception

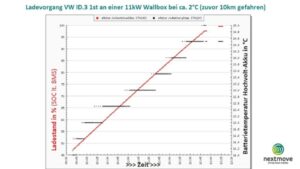

And immediately one more question behind: Doesn’t the battery also heat up passively during normal charging on a wallbox? Yes, it does. This was also tested and we show the values for a charging process with 11 kW power. The battery has become approx. 1 degree warmer in one hour. This effect can of course be used to charge the car in winter at the exact departure time, although VW does not recommend charging to 100 percent in everyday use. But you have the effect, even if the car is only charged up to 80 percent.

Fast loading of the ID.3 in winter?

Or the question from many new owners of ID3 or other e-cars: „My car only loads XY kW. I thought it could do twice that. Is my car broken? Is the charging station to blame?“ These are the questions that are then asked.

The current state of battery technology in all our e-cars is that the battery does not tolerate as much power in cold weather and therefore the charging capacity is reduced. The manufacturers also deal with this challenge very differently. Of course, the manufacturer can set priorities here already in the product development or in the purchasing department by choosing the cell manufacturer and the used cell chemistry, how important the winter characteristics are. Or/and the manufacturer can solve it by means of active thermal management.

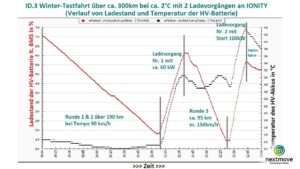

We show the values for one of the two ID.3 in the test sequence, the behaviour of the two cars was almost identical.

Our annotated raw data graph shows over four hours the course of the battery charge level and the temperature curve of the battery, between 10 and 44 °C. Before the shown test cycle we charged a few minutes to bring both cars up to 75 percent. At the start both cars had the known value of 13 °C battery temperature and were then driven over 190 km at a speed of 90 km/h. The battery did not heat up during this process. The airstream even cools the battery down a bit.

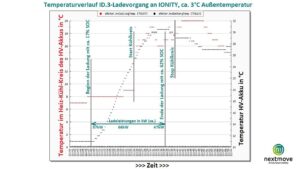

On arrival at the first charging stop with less than 20 percent charge level, the charging capacity was in the range of 55-65 kW. The vehicle did not actively heat the battery in addition, this shows temperature from the heating circuit.

Arriving at the first charge stop with less than 20 We see the battery temperature rise, but the heating circuit does not change at all during the first minutes of charging. Only at about 25 °C battery temperature the ID.3 starts the circuit, but not to heat, but to catch the battery temperature at about 30 °C. The ID.3 is, so to speak, content with charging capacities in the range of 60 kW. Because it does not heat, the user stands a few minutes longer, but has less losses. Whether we will soon see a navigation-based intelligent preheating of the battery at VW in the preview of such a fast charging process as at Tesla or Porsche, we do not know yet.

In the further course of the test drive over 95 km at 150 km/h the battery remains warm or even became even warmer despite the wind. The wave movement in the graphic is caused by the thermal management.

When we arrived at the second charging stop the battery had 28°C and both cars could be charged with maximum power of 101 and 104kW. The temperature continued to rise while charging. In the graphic we can see that the temperature went up again steeply during the second charging process. Maximum is 44°C. So the thermal management allows higher temperatures than during the charging stop before.

Our conclusion in this discipline: The software currently prioritizes efficiency over maximum charging power, but from the second charging stop, the ID3 should be able to get full power on the fast charger even in winter. Users should plan the charging stops in such a way that they arrive at the fast charger in the range of 10-20% charge level. Maybe the car will take over this planning soon.

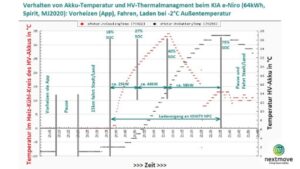

Winter behavior Kia in comparison

How does the competition from Korea feel about winter efficiency, preheating, battery heating and fast charging. Representative for the current vehicles of Hyundai and Kia with the 64 kWh battery, which probably all behave the same, we show the test run of a KIA e-Niro.

Preheating via app: The battery remains cold even though it was only about 1 °C. Driving off with an almost frozen battery does not matter to the car. The battery is not heated. The consumption remains low on short trips. The so-called winter mode was activated by the way.

When arriving at the quick charger, the car charges on the 2 °C cold battery with 25 kW power. That sounds little, but a Tesla battery would probably not have charged at all, but would have just heated up the car. Now the Kia also heats up.

After about 14 minutes the system has the battery at 5 °C, which is enough for the next jump then 44 kW charging power. You can’t see the charging power in the graphic, because only two values can be displayed at a time. Therefore it was determined in parallel and entered in the graphic. After another 16 minutes the battery is at 15 °C and the charging power jumps up to 58 kW, which is relatively close to the technically possible optimum for this platform of 72 kW power.

The heating circuit had hurried ahead and at this point already has 34 °C and at the same time decides that enough is heated. 58 kW charging power must be enough, after all, the Koreans are economical cars. But the time lag also shows the inertia of the systems. Because of the high mass of the battery, it certainly requires some testing by the manufacturers to find the right thresholds and switching points. So Kia does it differently than VW. VW heats the battery in cold weather at every start and at the fast charger the battery has to get to temperature by itself. KIA leaves the battery cold in everyday life and only heats it when it is on the quick charger.

In the future, VW will also be able to use software updates to adjust and continuously optimize the vehicles of the new modular system in its fleet. We are curious to see how VW performs in this discipline.

(Images: Hyundai (2), nextmove)